Free-Flex® Pivot Bearing

Engineering DatA

A unique bearing concept for applications with limited angular travel.

Riverhawk produces the patented Free-Flex flexural pivot for aerospace, commercial and industrial bearing applications involving limited angular travel. As an alternative to rolling element bearings and other devices providing rotational support for limited angular rotation, the Free-Flex pivot offers superior operating characteristics. It has demonstrated performance and installed cost advantages over conventional bearings in many applications.

The Free-Flex® pivot is a frictionless, stiction-free bearing ideally suited for angular deflection (rotation) of up to 60°. It is a simply packaged, compact, easily installed bearing with high radial stiffness (up to 100,000 lb/in), no backlash, no metal-to-metal contact and having predictable and repeatable performance. The pivot is ideal for precise positioning: adjustments in 0.00005-inch increments can be made with no lost motion. The unique combination of performance characteristics found only in Riverhawk Free-Flex® pivots is often the enabling technology which makes a component or subsystem design approach practical.

Free-Flex® pivot bearings consist of flat springs crossed at 90° and a supporting cylindrical counter-rotating sleeve. Friction, stiction (the force required to cause one body in contact with another to move), fretting corrosion, lubrication, “space welding” and lubricant out-gassing in space vacuum applications are all avoided in the Riverhawk Free-Flex® pivot because there is no metal-to-metal contact. By matching pivot size and spring rate to the application, cyclic stress on the springs may be maintained at a low enough value to assure infinite cyclic life. To demonstrate this life, a Free-Flex® pivot bearing was cycled for over 12 billion cycles over a period of twenty years, outliving several of the machines used to test it.

Free-Flex® pivots are available in two basic mounting configurations: cantilevered to support an overhung load; and double-ended to bridge-support a central load. Stock diameter sizes range from .125 in to 1.0 in, withstanding radial loads to 1600 lb in both series. Standard sizes in several torsional spring rates are available off the shelf in both cantilevered (Series 5000) and double-ended (Series 6000) designs to match user load and mounting requirements. The materials nominally used for standard pivots are AISI 410 or 420 corrosion-resistant steel for the bodies, and AISI 420 corrosion-resistant steel for the flat spring flexures. Normal assembly is by brazing the springs to the body halves. For application-specific requirements such as elevated ambient temperature the springs are electron beam welded to the body. Special spring materials include Inconel, beryllium copper and titanium. Special configurations are available upon request.

Major Performance Characteristics for Free-Flex® Flexural Pivots

- High Radial Stiffness

- High Axial Stiffness

- Frectionless

- Stiction-Free

- Not Susceptible to False Brinelling

- Low Hysteresis

- Low Centershift

- Exceptional Repeatability

- Predictable Performance

- Lubrication Not Required

- Maintenance Not Required

- Electrical Continuity

- Infinite Cycle Life (See Life Curves)

- Ambient Temperature Range of -400° to +250°

Additional Characteristics for Free-Flex® Flexural Pivots

- Radiation Resistance

- Low Thermal Drift

- No Rubbing Surfaces

- Contaminant Tolerant

- Operates in Vacuum of Space

- Self-Centering

- Reliable

Summary Statement

The Free-Flex® Flexural Pivot is an elegantly simple bearing that provides precise single-plane positioning and frictionless motion of limited angular rotation devices.

glossary of flexural pivot terms

This load is also called “Thrust Load”. This Load acts in direction of longitudinal axis of Pivot

The number of pounds of axial (thrust) load necessary to create a specific unit of relative motion between the flexure-connected portions of the pivot in the longitudinal direction. It is usually stated as pounds per inch. For example, an axial load of 50 pounds is found to create a motion of 0.001 inches; the axial rate is 50 divided by 0.001 inches or 50,000 pounds per inch.

The difference between the diameter centers of the moved portion of the pivot and the portion (or portions) that are fixed. Basic center shift is a kinematic characteristic that occurs in more or less degree as a function of the angle deflected; it occurs the full length of the shifted diameter.

An auxiliary center shift is mechanical and is caused by radial load (see “Radial Rate”). Shift of the full length of the diameter does not theoretically take place, but for practical purposes, within the pivot standard dimensions; it is considered as taking place the full length of the pivot diameter

One cycle is the sum of angular motion from the null position to a particular angle, the return to the null position, the angular motion from the same angle in the opposite direction and the return to null.

A radial load directed such that it bisects the crossed flexures and is parallel to the travel slots.

A radial load perpendicular to “V load”; see “H Load” and “V Load”.

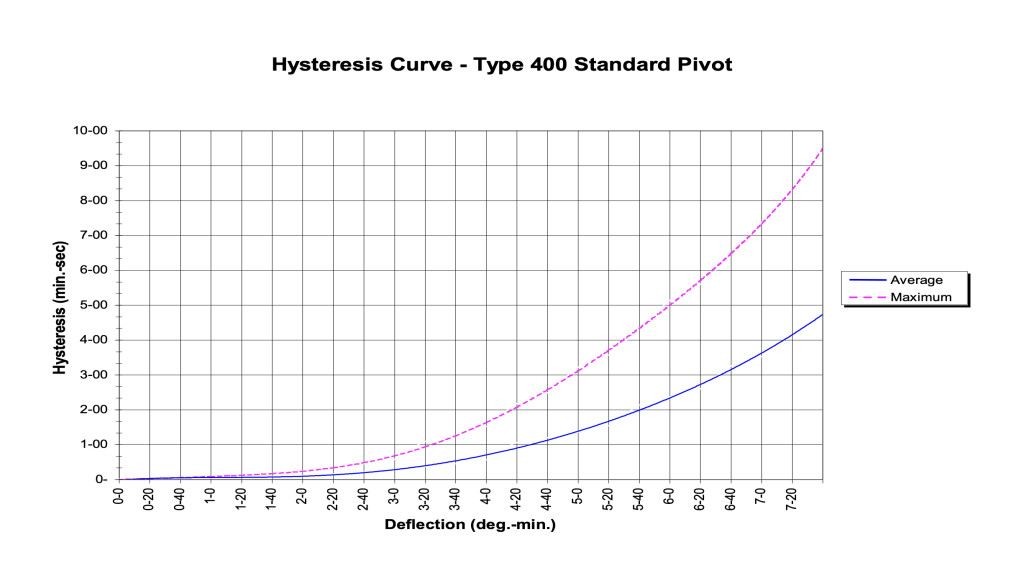

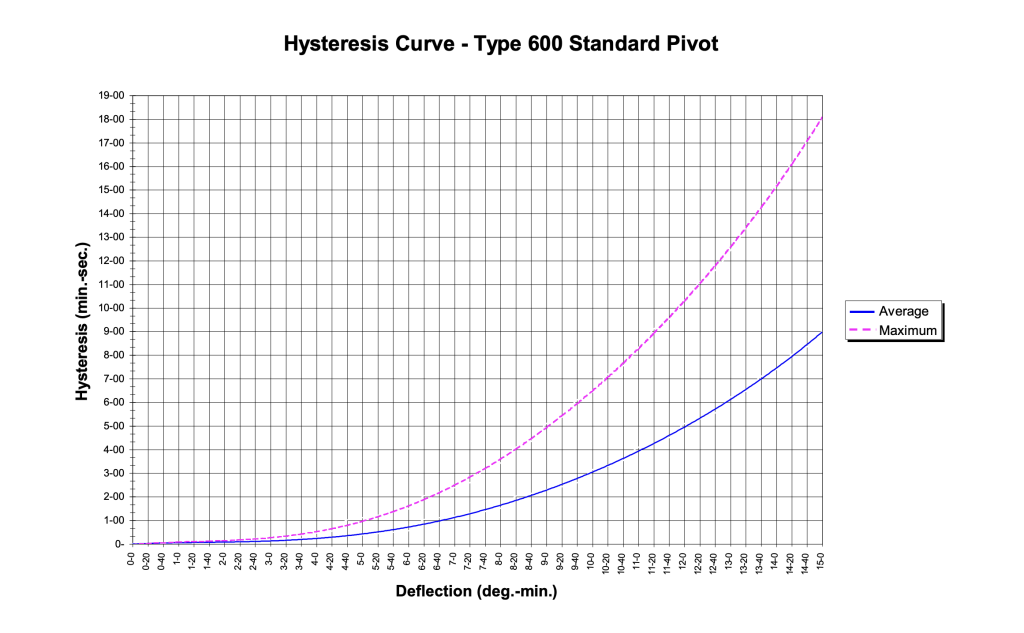

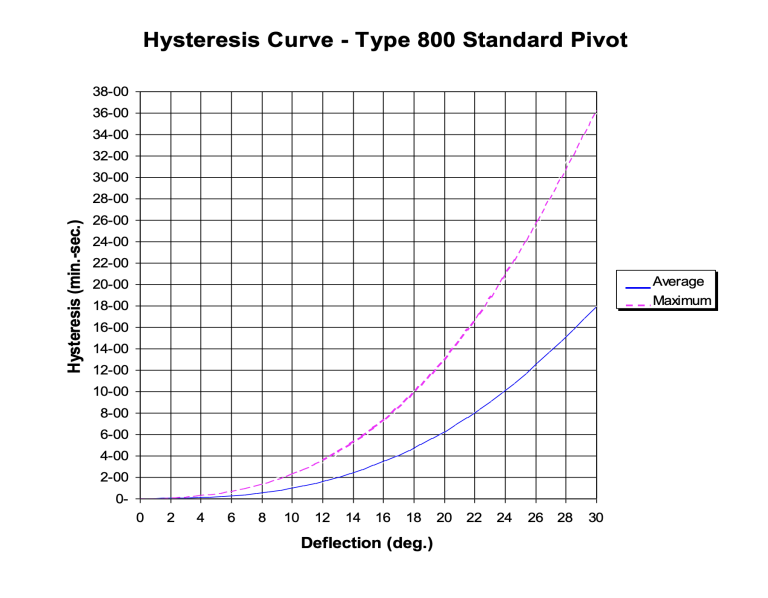

The total amount of variation from null position when a torque is applied such as to produce a complete cycle. It is expressed in minutes or seconds, as applicable.

“K” is a designation for “Torsional Rate” used in the torsional rate equation.

The degree which a plot of torque (about the longitudinal axis) vs. deflection is a straight line.

A torque applied in a given plane through a pivot other than around the longitudinal axis. RIVERHAWK Engineering usually considers it as a torque in addition to that caused by an offset V, H or T load.

The total torque applied in a given plane through a pivot other than around the longitudinal axis. It is the algebraic sum of moments caused by radial and thrust loads and any additional from other sources.

The amount of torque necessary to rotate the pivot a specific angle. This term, although related to “Torsional Rate”, is not identical to “Torsional Rate”.

The degree which a plot of torque (about the longitudinal axis) vs. deflection varies from a straight line; it is the opposite of linearity.

The position of zero angular travel when the pivot is under no load, with no applied torque about any axis and at a specific temperature.

The change in the null position due to effects other than applied loads and/or torques. This term is not to be confused with hysteresis.

A radial load directed directly through either the outer spring or inner spring which results in a tension load.

A radial load directed directly through either the outer spring or inner spring which results in a compression load.

A radial load directed such that it is directed exactly in line with a pivot flexure.

A load directed to the pivot center from any angle around the pivot circumference.

The number of pounds of radial load necessary to deflect the pivot structures (as measured at the outer diameter) a specific unit of measure. It is usually stated as pounds per inch. For example, a radial load of 10 pounds is found to deflect the pivot 0.0001 inches; the radial rate is 10 divided by 0.0001 inch or 100,000 pounds per inch.

There are 2PI radians in every 3600 (circle), thus one radian is 57.2956 + degrees. In general, the value of 57.30 is used.

See “Axial Rate”.

See “Radial Rate”.

See “Torsional Rate”.

RIVERHAWK applies this term exclusively to express “Torsional Rate”. Technically, however, since other rates are also through the springs, they could be considered as Spring Rate”, but it is not done. See “Torsional Rate”.

See “Axial Load”.

The amount of torque necessary to rotate the pivot per unit of rotating motion. This is generally in terms of pounds-inches per radian, but pound-inches per degree are also common usage. Designation is “K”.

A load directed to the pivot such that the highest flexure stress compression.

A load directed to the pivot such that the highest flexure stress is tension.

A radial load directed such that it bisects the crossed flexures and is perpendicular to the travel slots.

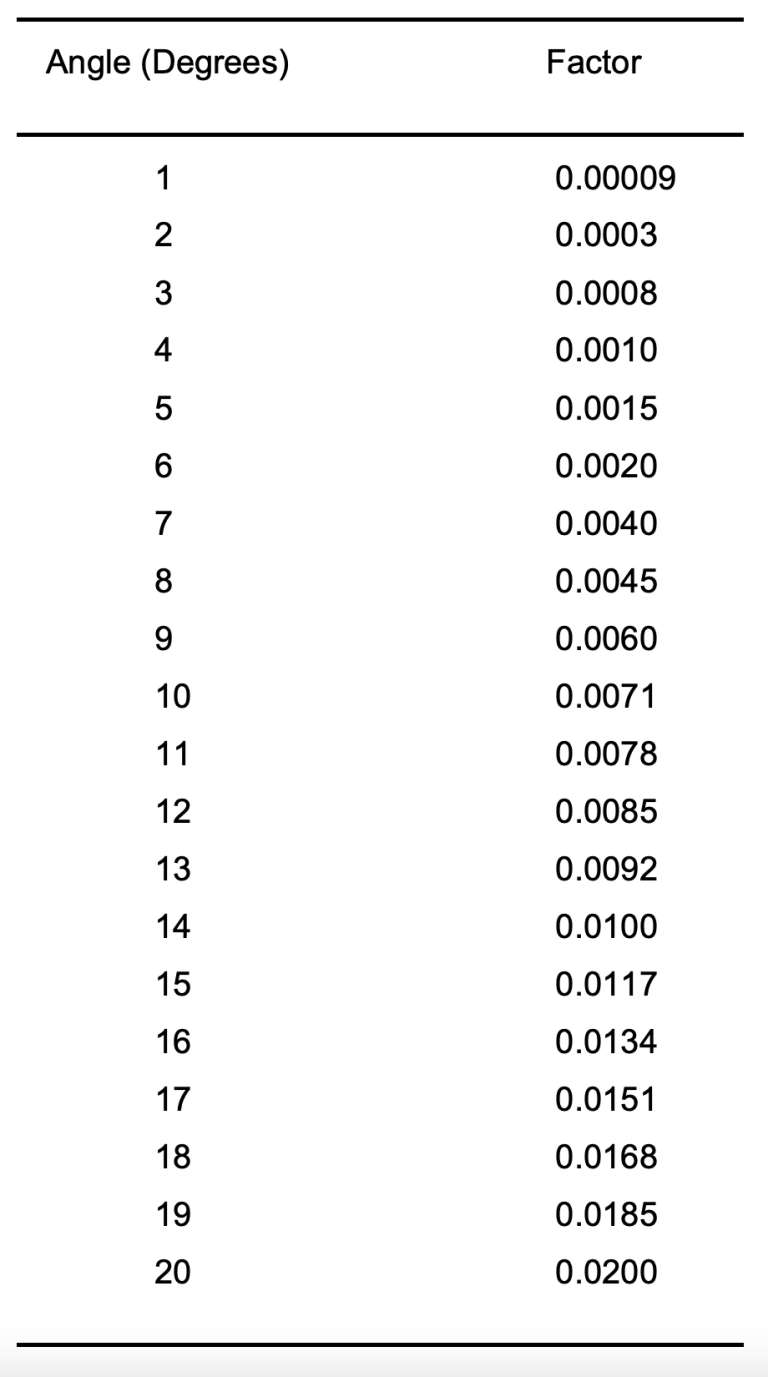

CENTERSHIFT vs. ANGULAR DEFLECTION AT NO LOAD CONDITIONS

To determine centershift at any particular degree, multiply the diameter of the pivot by the respective factor shown below. For example, to determine the centershift of PN 5020-800 (0.6250 inch diameter) at 4 degrees, multiply 0.6250 x 0.001 = 0.000625 inch.

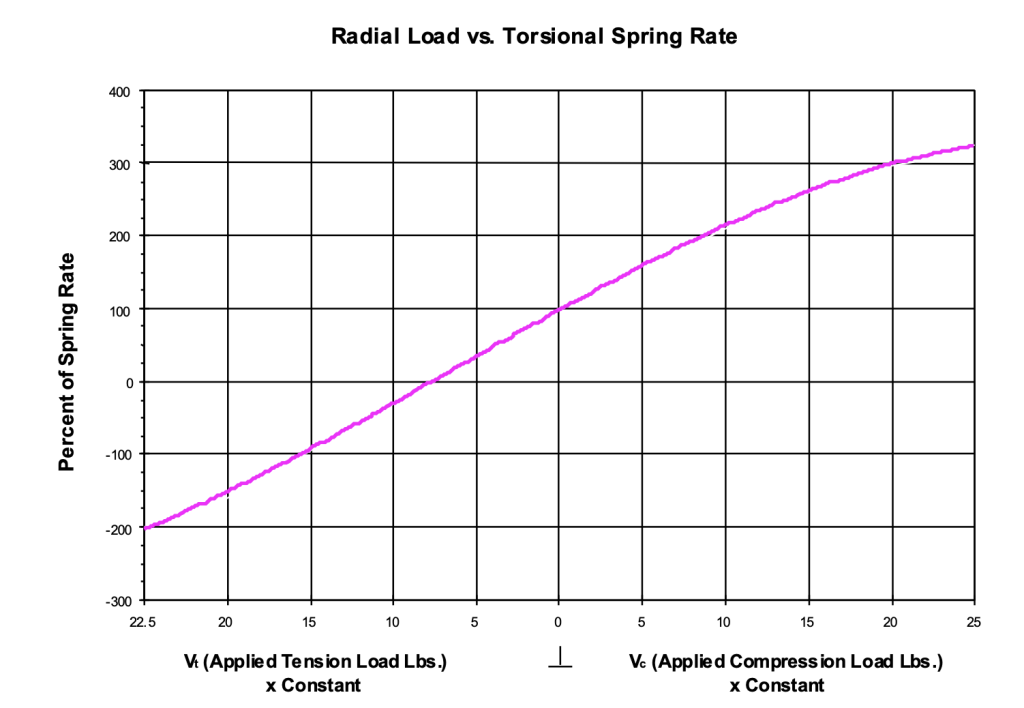

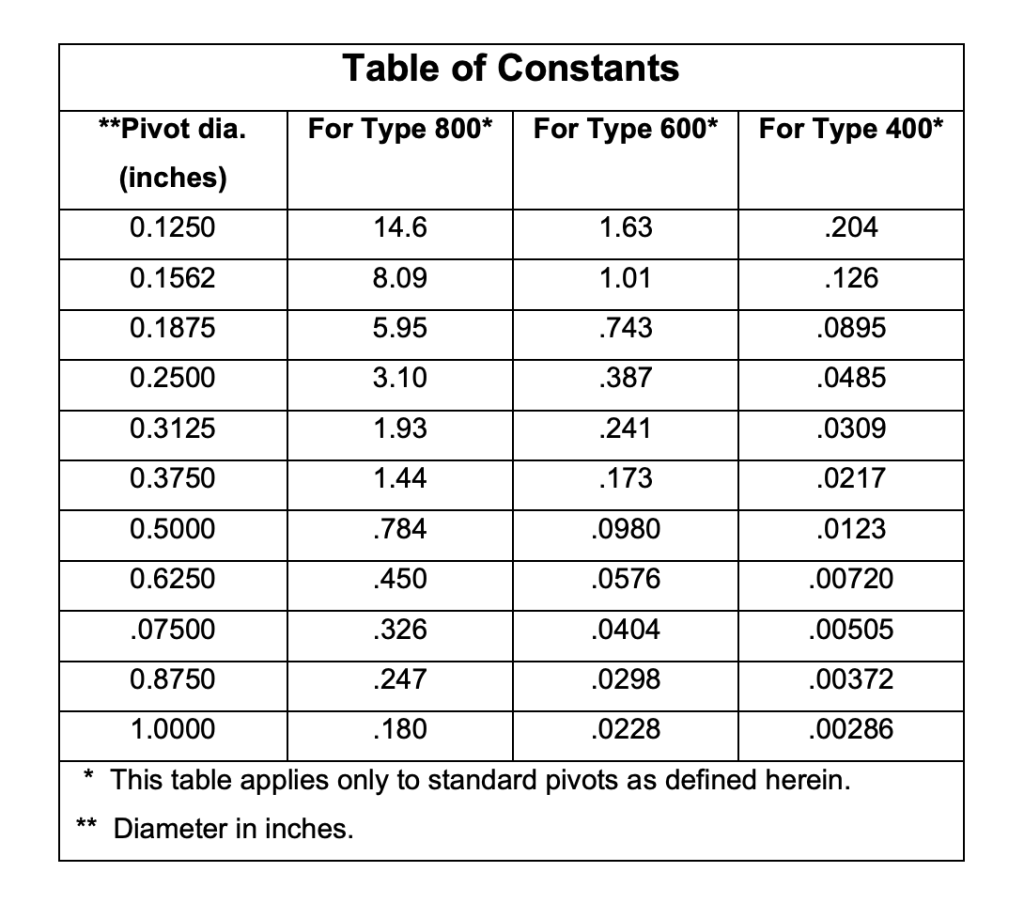

torsional spring rate

Torsional spring rate values remain constant throughout rotation. In order to calculate torsional spring rate values of a pivot under load, multiply your load value by the constant found in the table of constants above.

*Note that in tension, graph shows torsional spring rate values dropping below zero. In a situation like this, the spring would be considered unstable, and therefore lose its ability to restore itself to the null position after being rotated.

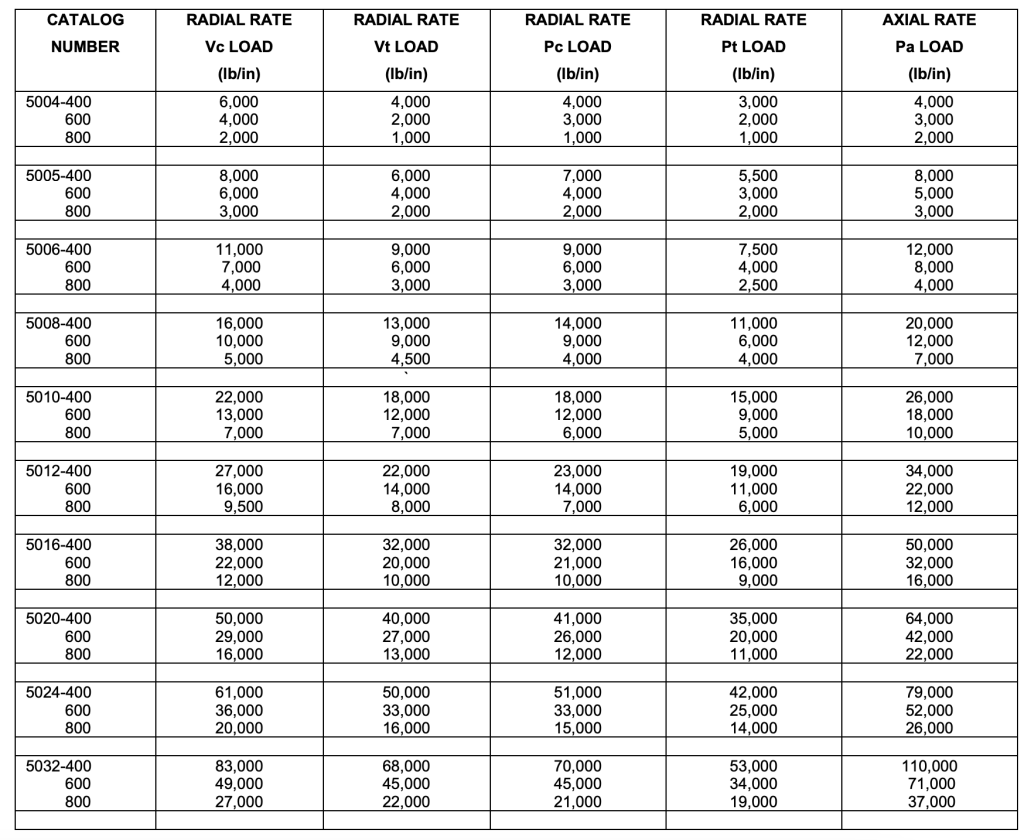

pivot stiffness data

With reference to the flex pivot stiffness data provided in the “Dimensions and Characteristics” table on page 2 of the Free Flex Pivot® catalog, it should be understood that this data is for reference only and Riverhawk does not guarantee that the product will meet these values. The data was developed by empirical results (testing) obtained via an assortment of pivot types and sizes over a period of time and represents the average values for the specific pivot groups tested. This testing was performed on the cantilever type pivot (5000 series) loaded at the midpoint of the unsupported half.

If cantilever pivots are used as a pair on a common axis and are interconnected with a very stiff piece of hardware, the radial stiffness value for each pivot can be assumed to be 1.25 times the value indicated in Table 1. This is a result of the moment (cantilever) bending being restrained, putting the pivot essentially in pure shear.

A double-ended (6000 series) pivot evenly loaded in the center of it’s length is approximately 2.5 times the radial stiffness of an unsupported cantilever pivot, and the values in Table 1 can be increasing by a factor of 2.5.

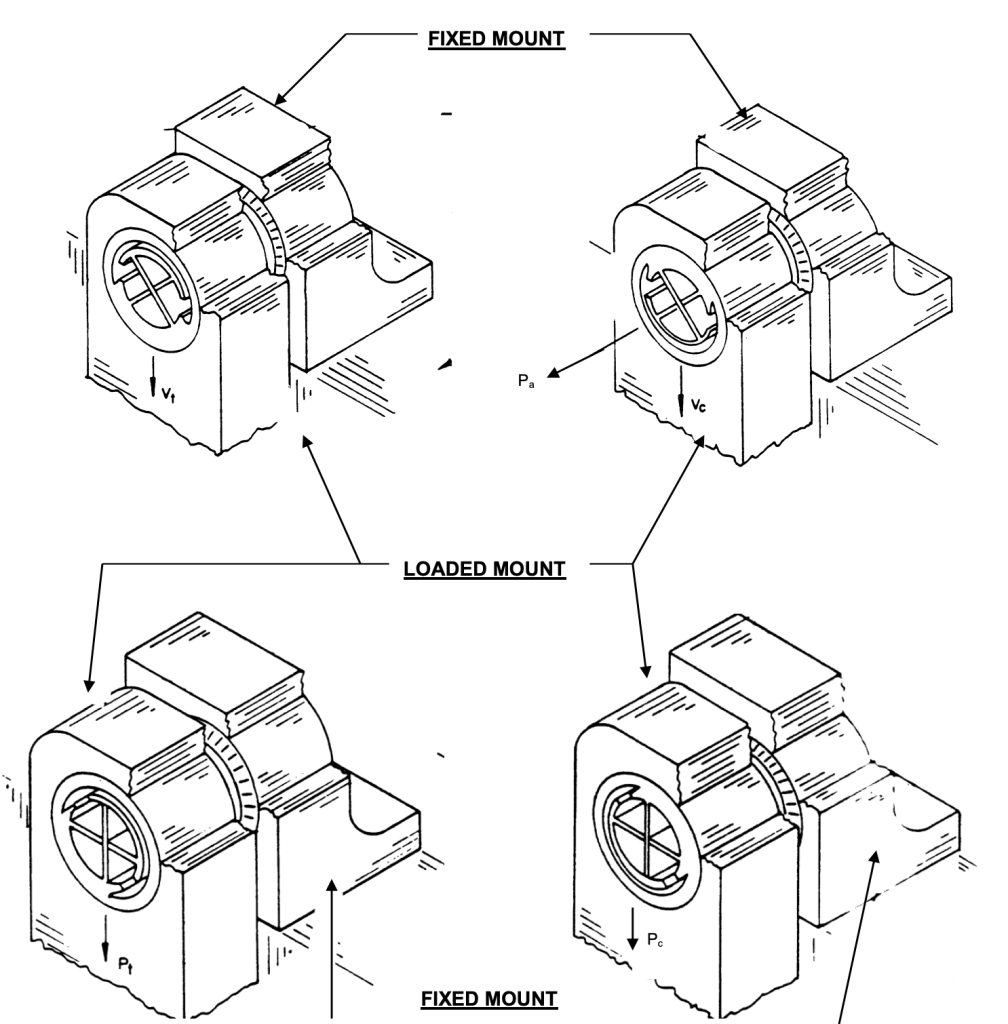

The columns provided in Table 1 represent a specific load vector as related to the angular orientation of the load with respect to the pivot flexures as shown in Figure 1 and Figure 2. A simple way to remember the designations is that the subletter “c” means “compression”, “t” means “tension”, and “a” means “axial”. “Compression” and “tension” refer to compression or tension stresses in the pivot flexures resulting from the applied load.

The “P” load is where the load is applied in line with the plane of a flexure. The “V” load is where the load vector is 45 degrees from the band between the flexures at the center of one of the arc-shaped halves of the pivot. The “Pa” load is an axial load applied at the pivot centerline.

The data applies only to standard brazed construction pivots as listed in our catalog. Special pivots must be considered independently.

table 1

Radial and Axial Siffness Data

Brazed Cantilever Pivots

NOTE:

1. The stiffness data presented above applies only to cantilevered (5000 series) brazed pivots loaded at the mid-point of the unsupported half at 0 degrees deflection.

2. For double-ended pivot (6000 series); multiply the Radial Stiffness values by 2.5 for the same diameter and flexure class. There is no change in axial stiffness.

3. For a system of tandem-mounted cantilevered pivots (5000 series) connected very stiffly, multiply the radial stiffness values by 1.25 for each pivot in the system

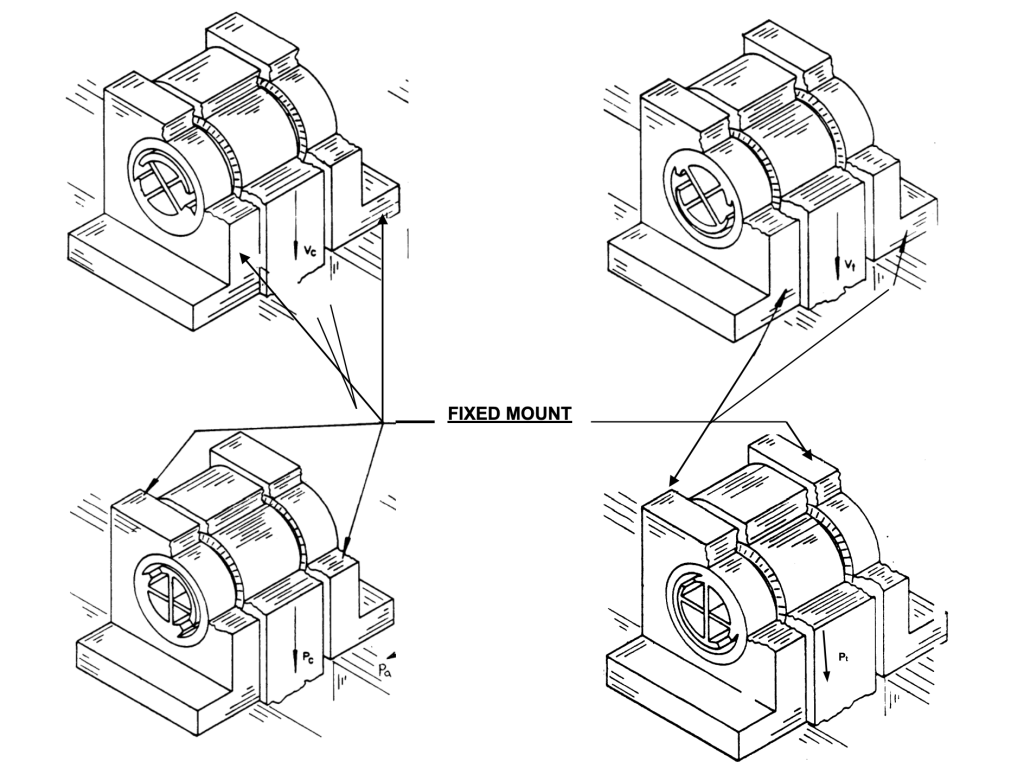

Figure 1

Double End Supported Pivots

WHERE A Pt OR Vt CONDITION EXISTS A Pc OR Vc CONDITION MAY BE OBTAINED BY ROTATING THE PIVOT 180 DEGREES OR CONVERSELY A Pt OR Vt MAY BE OBTAINED FROM A Pc OR Vc LOADING BY ROTATING THE PIVOT 180 DEGREES WITHIN FIXED MOUNT.

FIGURE 2

Cantilever Pivots

To learn more about Riverhawk’s Cantilevered (Single-Ended) Pivot Bearing, please contact a member of our team. We are happy to assist you with your project needs.