Suggested Methods of Mounting Free-Flex® Pivots

For most applications, Riverhawk recommends orientation of the pivot to operate with a Vc load condition. Vc load is defined as a pure radial load located 90° from the clearance slots, which will tend to place the flexures in compression. Additional details regarding the effect of various kinds of loading on the performance of the pivot may be obtained from Riverhawk, but are outlined in our Flexural Pivot Engineering Data brochure.

The attached pages will show various methods of pivot mounting. The first seven methods are applicable to the standard Free-Flex® pivots available from stock.

The remaining methods of mounting shown are not applicable to stock pivots, but can be accommodated through special order pivots upon request. Contact Riverhawk Company or your nearest Riverhawk Company Free-Flex® Pivot distributor for a review of your special mounting needs.

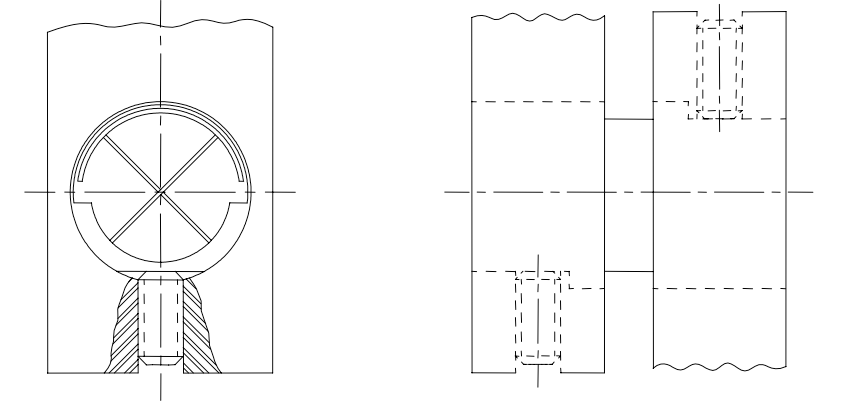

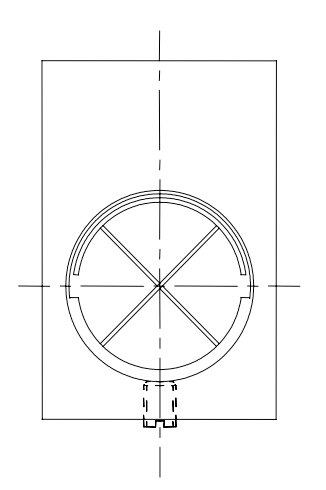

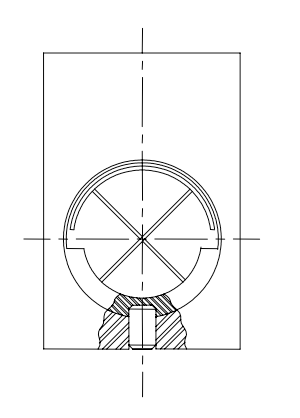

screw clamp

Hole Diameter is to be 0.0005 to 0.0015 inch larger than the pivot diameter.

When vibration is anticipated, standard-locking methods should be used on the clamping screw.

Clamp stresses may be reduced by drilling and slotting as shown by dotted outline.

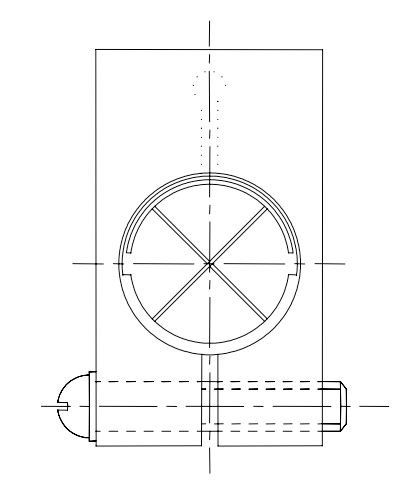

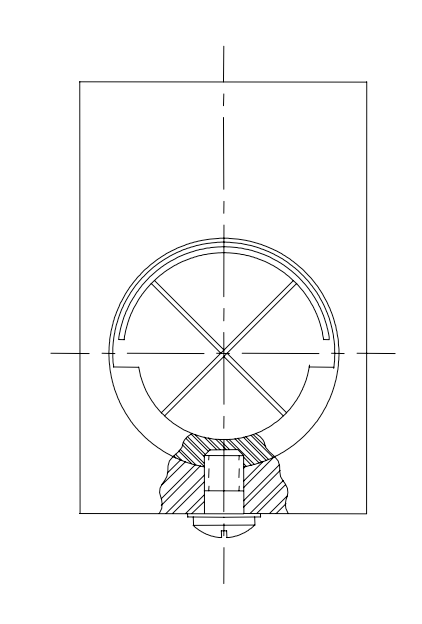

SPRING CLAMP

Suitable for low torque requirements.

Optimum diameter of the hole is a function of the material used and the pivot torsional spring rate. Clamping force must be just high enough to prevent rotational slippage of the pivot without distorting the pivot.

Clamp slot must be spread for pivot insertion. Caution must be used to prevent permanent deformation of the clamp during spreading

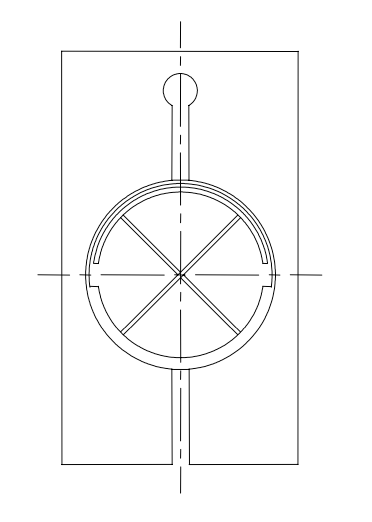

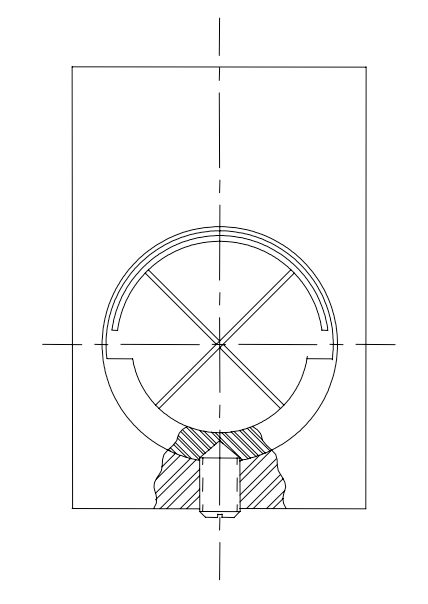

SET SCREW

Hole diameter to be 0.0005 to 0.0015 inch larger than the pivot diameter.

Cup point set screws are recommended.

Use caution when tightening set screw to not crush or distort pivot

When vibrations are anticipated, standard screw locking methods should be used on the set screw.

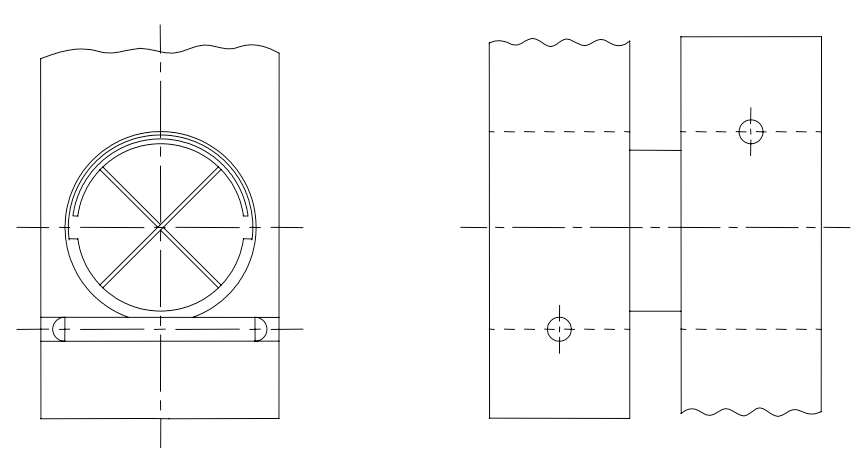

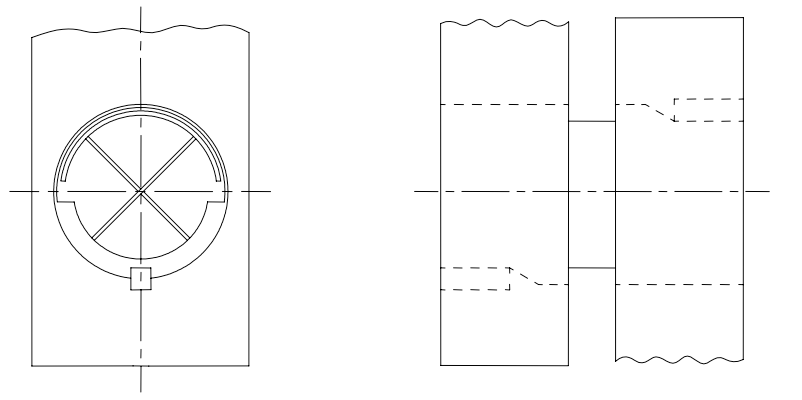

RADIAL PIN

AXIAL PIN

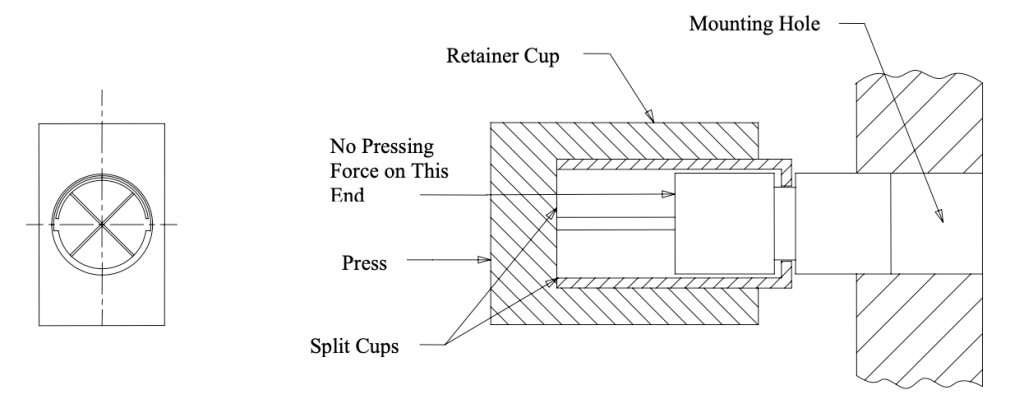

SHRINK OR PRESS FIT

American Standard shrink fit tolerances may be used. Pivot can be soaked in dry ice without damage.

Mating part should be quenched rapidly after assembly to avoid overheating of pivot.

Pivot temperature should not exceed 800°F at any time during assembly

For press fit installations, special tools are required to avoid shearing off of outer sleeve or damaging flexures.

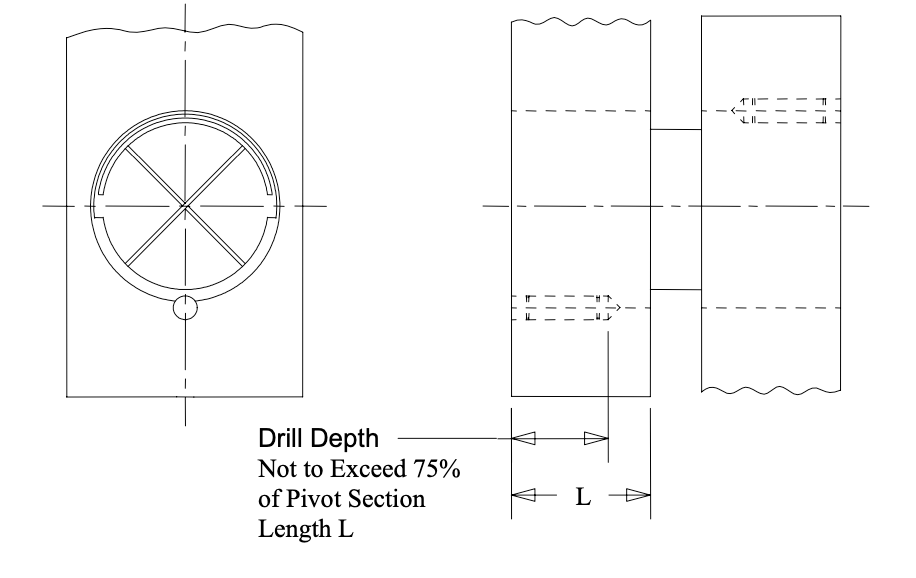

DOWEL PIN

Hole diameter to be 0.0005 to 0.0015 inch larger than pivot diameter.

Drill and ream dowel pin hole at time of assembly

Insure the pin, drill and reamer do not touch flexures at any time.

NON-STANDARD PIVOT INSTALLATIONS

TAPPED HOLE

Mounting Hole to be 0.001 to 0.003 inch larger than pivot diameter. The larger clearances are applicable to the larger pivot sizes.

The screw length must be controlled to prevent interference with the flexures.

DRILL POINT

Hole diameter to be 0.0005 to 0.0015 inch larger than pivot diameter.

The drill point should be standard 120° included angle

Use caution when tightening set screw to prevent distortion or collapse of the pivot

KEY WAY

Hole diameter to be 0.0005 to 0.0015 inch larger than pivot diameter.

Recommended key slot dimensions will be supplied when complete details of requirement are identified.

FLATS

Hole diameter to be 0.0005 to 0.0015 inch larger than pivot diameter.

Cup point set screws are recommended.

Use caution when tightening set screw to prevent distortion or collapse of the pivot.

When vibrations are anticipated, standard screw locking methods should be used on the set screw.